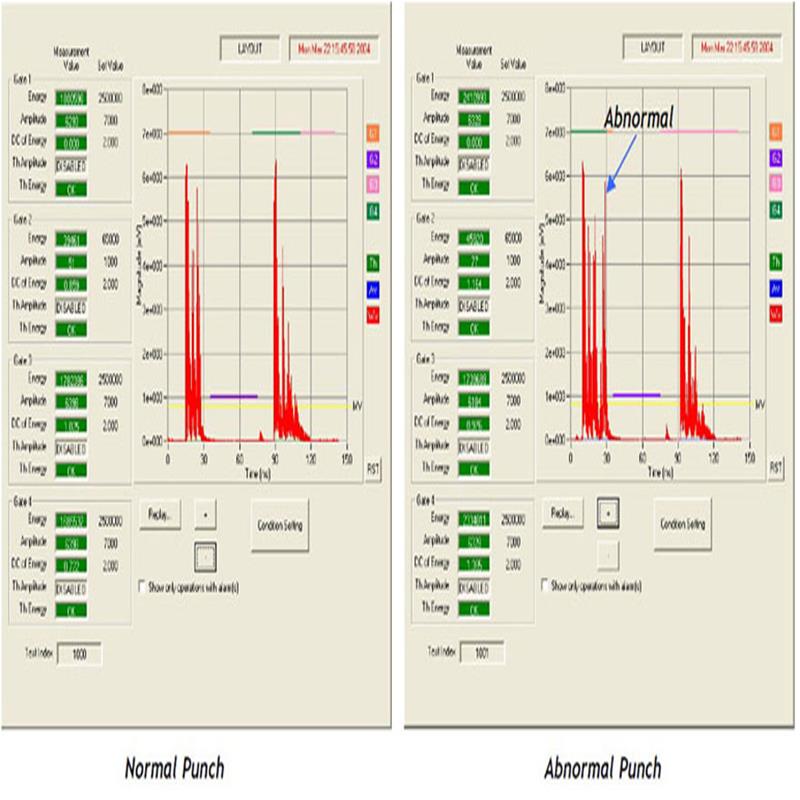

Punch Press Monitoring

The Punch Press Monitoring System (PPMS), from Physical Acoustics Corporation (PAC), was designed for real time quality control and tool failure detection of punch press processes. The PPMS uses acoustic emission (AE) technology to detect very high frequency (>100 kHz) signals that are generated due to plastic deformation or cracks in the materials (tool, part and die) during punch processes. An ideal production process monitoring system, the PPMS provides early detection of tool or die failure and deterioration of production quality due to the tool failure, part crack and other irregular process conditions. The system helps to prevent catastrophic failure that may result in damaging important components or shutting down the punch press for major repair.